Sure, diesel and gasoline engines are more alike than they are different. But knowing those differences can help you immensely when you’re working under the hood.

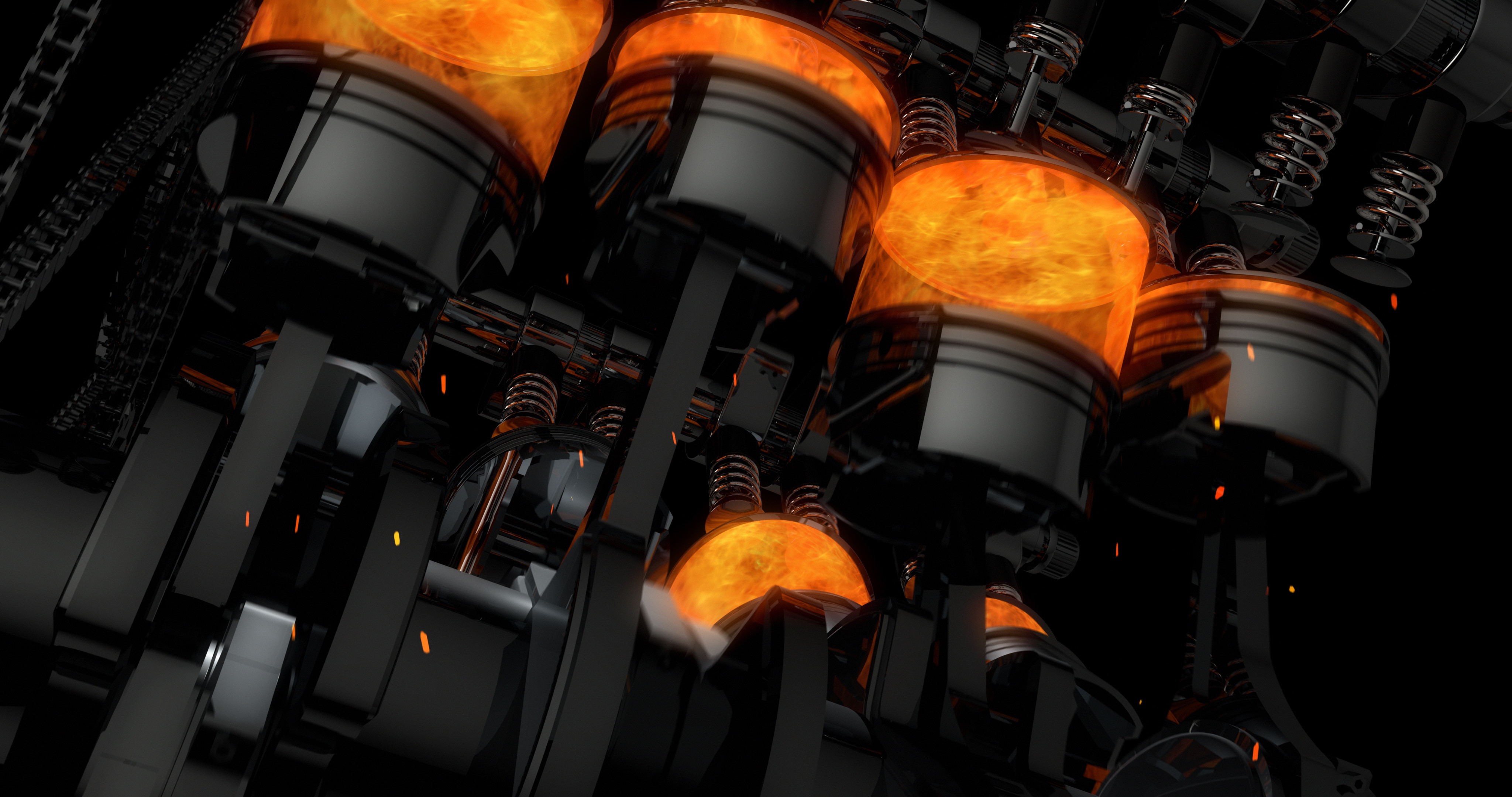

Both diesel and gasoline engines are internal combustion engines that convert chemical energy into mechanical energy by oxidizing a fuel to heat air. Diesel engines are referred to as “compression ignition” while gasoline engines are called “spark ignition.”

We’ve all seen the results of oxidation (also called combustion), where oxygen combines with another element and releases energy in the form of heat. That steak you burned on the grill? It wasn’t your fault, it just oxidized too quickly. Oxidation rates increase with temperature, so the hotter it gets, the faster it goes.

So as we oxidize fuel in an internal combustion engine, the heat produced expands the air, which produces pressure. Engines are basically air pumps, and the more air you move through them, the more power you can make

That pressure created in the cylinder is the source of power, and engine power is usually limited by the peak cylinder pressure during a combustion event.

Remember, cylinder pressure pushes the piston, which turns the crankshaft, creating work. If the pressure exceeds the load capability of the engine components, dreadful things can happen.

An engine is a series of controlled oxidation events that heat the air and produce power. The difference in a gasoline and a diesel engine is the way these combustion events are initiated and the peak pressure achieved.

Diesel engines compress only air in the cylinder, and then when it is near the end of the compression stroke, fuel is introduced into the combustion area via a high-pressure spray—pressures way higher than your pressure washer.

Gasoline engines differ from diesels by adding the fuel to the air before oxidation is initiated. Gasoline engines compress a controlled mixture of fuel and air, and then oxidation is started by adding a spark. Since gasoline engines are compressing a mixture, they can inject the fuel at several locations: direct injection, port injection, throttle body injection, or a combination of direct and port, or even carbureted, which is not injection at all.

These different types of injection work in different ways.

Carbureted gasoline engines were all the deal through the 1970s. However, carburetors do not allow the fuel and air mixture control necessary to make the kind of clean power we have today. Ever since throttle body injection replaced carburetors in the 1980s, the fuel is injected at the top of the intake manifold. Essentially, we just replaced the carburetor with a different device.

As time moved on, expectations for increased fuel economy and power drove the injectors into the intake port of the cylinder head—ergo, port injection—which led to the birth of the modern gasoline engine. From that point, engines continued to improve, and injectors moved into the combustion chamber, which created today’s state-of-the-art modern engine, known as direct injection.

In summary, picture both of our engines. Both are ready to initiate oxidation of fuel, both are at pressure, but one has gasoline mixed in and one has diesel fuel in the injector waiting for the magic to begin. The rest of the process is the same: fuel is oxidized, heat is created, pressure increases, and the piston is pushed down in the cylinder. The difference is ignition.

- Prior to using or installing any of these products always consult your vehicle’s owner’s manual for compatibility and warranty information.

- Always take appropriate safety precautions when working on or operating your vehicle. Take the necessary steps to help prevent injuries; always use protective gear like helmets, safety goggles, and gloves.